Key Performance

A ball valve can rotate 90°, and its rotary plug is a spherical ball with a circular through-hole or passage along its axis. Ball valves are primarily used in pipelines to shut off or divert the flow of a medium, and they can change the direction of flow. The valve can be tightly closed with a simple 90° rotation and requires minimal rotating torque. Ball valves are most suitable for use as on-off and shut-off valves. Among them, the hard-sealed V-ball valve has a strong shearing force between the V-shaped ball core and the metal valve seat with hard alloy overlay, making it suitable for media containing fibers, tiny solid particles, and similar substances.

The main characteristics of a ball valve are its compact and simple structure, providing reliable sealing and convenient maintenance. The sealing surface and the ball surface are typically in a closed state, making it resistant to erosion by the medium. Ball valves are easy to operate and maintain, suitable not only for general working media such as water, solvents, acids, and natural gas, but also for harsh working conditions with media like oxygen, hydrogen peroxide, methane, and ethylene. Therefore, they are widely used in various industries. Its valve body can be integral or composite.

Drive Mode

Manual, electric, pneumatic, elector-hydraulic, bevel gear, and so on.

Application Areas

The ball valve is widely used in industries such as petroleum refining, long-distance pipelines, chemical, papermaking, pharmaceuticals, hydraulic engineering, power industry, municipal services, steel industry, and others.

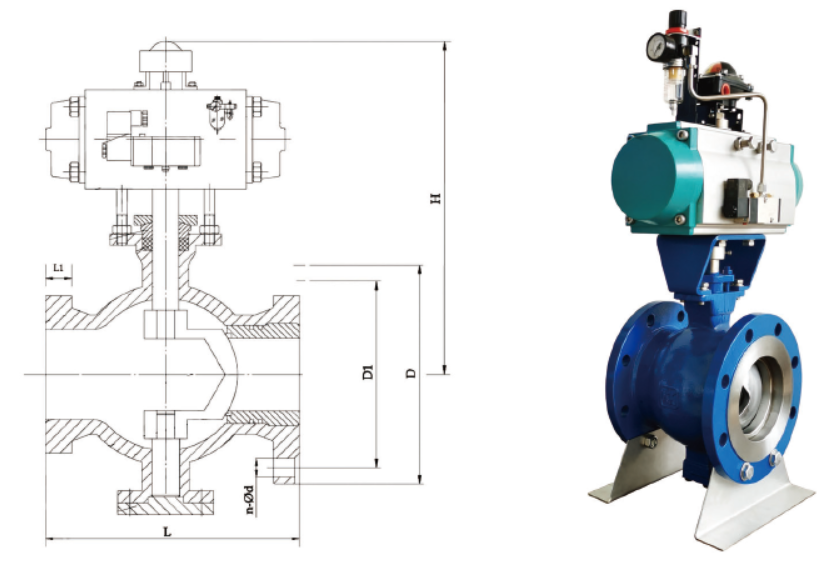

Main Dimensions of Wear-resistant V-type Ball Valve

|

Nominal Diameter |

PN1.6MPa Dimensions(mm) |

|||||

|

Structural Length |

Center Height |

Flange Outer Diameter |

Center Distance |

Flange Thickness |

Number of Holes - Hole Diameter |

|

|

25 |

102 |

277 |

115 |

85 |

16 |

4-Φ14 |

|

32 |

102 |

285 |

140 |

100 |

18 |

4-Φ18 |

|

40 |

114 |

305 |

150 |

110 |

18 |

4-Φ18 |

|

50 |

124 |

364 |

165 |

125 |

20 |

4-Φ18 |

|

65 |

145 |

379 |

185 |

145 |

20 |

4-Φ18 |

|

80 |

150 |

389 |

200 |

160 |

20 |

8-Φ18 |

|

165 |

||||||

|

100 |

180 |

402 |

220 |

180 |

22 |

8-Φ18 |

|

194 |

||||||

|

125 |

194 |

426 |

250 |

210 |

22 |

8-Φ18 |

|

150 |

215 |

453 |

285 |

240 |

24 |

8-Φ22 |

|

229 |

||||||

|

200 |

230 |

473 |

340 |

295 |

26 |

12-Φ22 |