Classification and Introduction of Wear-Resistant Pipes

Wear-resistant pipes can be divided into alumina ceramic pipes, silicon carbide ceramic pipes, and wear-resistant plastic alloy pipes.

Wear-resistant composite pipes leverage the high strength, good toughness, impact resistance, and excellent welding properties of steel pipes, combined with the high hardness, wear resistance, corrosion resistance, and heat resistance of ceramics. This combination overcomes the drawbacks of low hardness in steel pipes and poor wear resistance and toughness in ceramics. As a result, composite pipes exhibit excellent wear resistance, heat resistance, corrosion resistance, and comprehensive performance against mechanical and thermal impact, easy to be welded. It is an ideal pipeline for conveying grinding and corrosive medium, granular materials and etc.

Currently, the practices of dozens of thermal power plants have shown that ceramic-lined wear-resistant steel pipes have high wear resistance and strong resistance to fluid erosion. In a primary air duct, bends experience the fastest wear, and the wear resistance of ceramic-lined wear-resistant steel pipe bends is more than five times higher than that of thick-walled wear-resistant cast steel bends.

In practical applications, after opening for observation and measurements following 1-2 years of use, the ceramic-lined wear-resistant steel pipes show no significant wear or detachment in the composite layer. In terms of pipes with the same specifications and unit length, the weight of ceramic-lined wear-resistant steel pipes is only about half that of wear-resistant cast steel pipes or bimetallic composite pipe. This results in a 30-40% reduction in project cost per meter. Compared to cast iron pipes and REEs wear-resistant steel pipes, the weight of ceramic-lined wear-resistant steel pipes is only about 2/5, leading to a cost reduction of over 20% per meter. In corrosive or high-temperature environments, the cost of ceramic-lined wear-resistant steel pipes is only a fraction of that of stainless steel pipes or nickel-titanium pipes.

Application Area

These ceramic-lined wear-resistant steel pipes are extensively used in industries such as thermal power, steel, metallurgy, machinery, coal, mining, chemical, cement, port terminals, etc. They are employed in coal conveying systems, material conveying systems, milling systems, ash and dust removal systems, and other heavy-wear mechanical equipment. Different types of products can be selected based on specific needs and requirements.

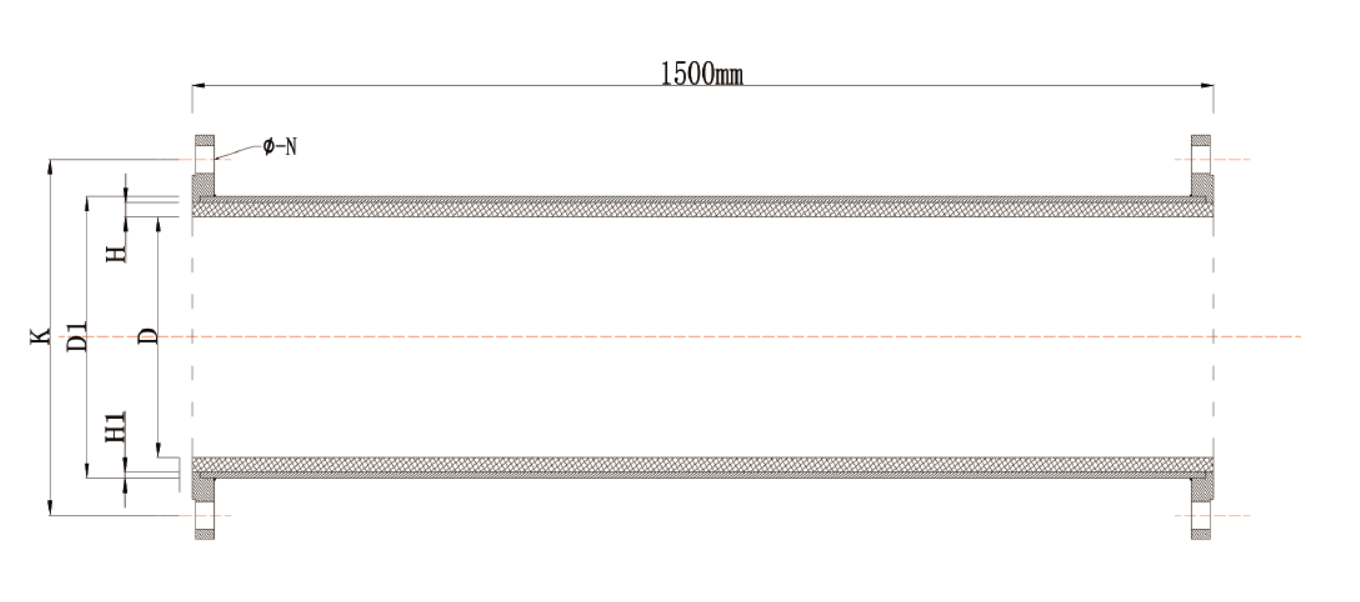

Main Dimensions of Ceramic Pipes

|

Nominal Diameter |

Wear-Resistant Pipe Dimensions(mm) |

1.0MPa Flange Dimensions(mm) |

Single Weight of Wear-Resistant Pipe (1.5 meters) with Flange |

||||

|

Steel Pipe Outer Diameter |

Steel Pipe Thickness |

Ceramic Thickness |

Pipe Inner Diameter |

Center Distance |

Hole Diameter - Number of Holes |

||

|

50 |

77 |

3.5 |

10 |

50 |

125 |

Φ18-4 |

28.79 |

|

80 |

108 |

4 |

10 |

80 |

160 |

Φ18-8 |

43.78 |

|

100 |

129 |

4.5 |

10 |

100 |

180 |

Φ18-8 |

57.29 |

|

125 |

154 |

4.5 |

10 |

125 |

210 |

Φ18-8 |

69.95 |

|

150 |

180 |

5 |

10 |

150 |

240 |

Φ23-8 |

85.27 |

|

200 |

234 |

5 |

12 |

200 |

295 |

Φ23-8 |

128.58 |

|

250 |

286 |

6 |

12 |

250 |

350 |

Φ23-12 |

180.25 |

|

300 |

336 |

6 |

12 |

300 |

400 |

Φ23-12 |

215.05 |

|

350 |

386 |

6 |

12 |

350 |

460 |

Φ23-16 |

267.6 |

|

400 |

440 |

8 |

12 |

400 |

515 |

Φ27-16 |

309.35 |

|

450 |

490 |

8 |

12 |

450 |

565 |

Φ27-20 |

346.95 |

|

500 |

552 |

10 |

16 |

500 |

620 |

Φ27-20 |

436.4 |

|

600 |

652 |

10 |

16 |

600 |

725 |

Φ30-20 |

524 |

|

700 |

756 |

12 |

16 |

700 |

840 |

Φ32-24 |

598.25 |