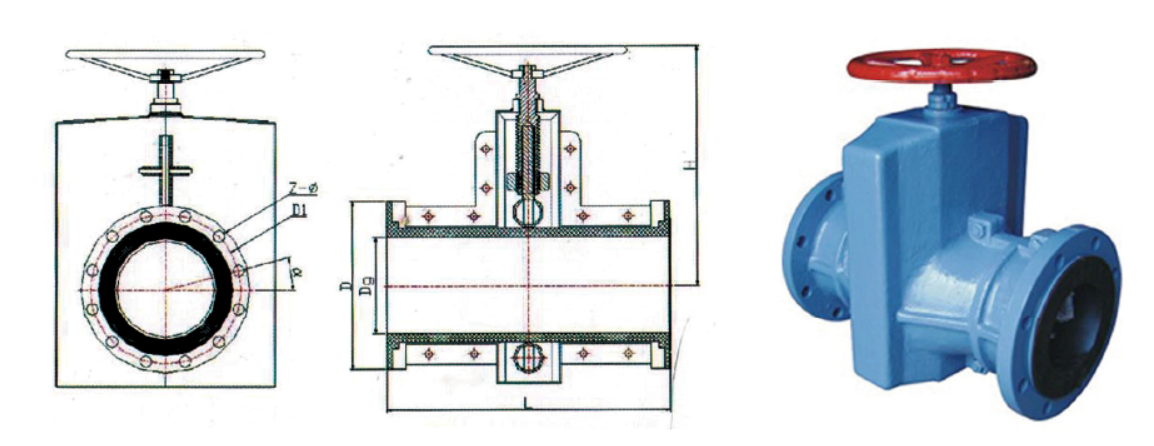

Pinch Valve (Hose Valve)

The hose valve is composed of a valve body, an opening and closing mechanism, and special rubber tubing.

Main Performance Features

The hose valve is composed of a valve body, an opening and closing mechanism, and special rubber tubing.

During operation, rotating the hand wheel clockwise reduces the water flow until it is completely closed. The structure of the pinch valve is simple, facilitating inspection and replacement of the rubber tubing. It has a versatile function, capable of replacing gate valves, stop valves, and regulating valves. The pinch valve exhibits good resistance to cold and wear, and various rubber tubing formulations can be customized based on user requirements.

- Multifunctional: it can be used as a substitute for gate valves, globe valves, and control valves.

- Wear-resistant and corrosion-resistant capabilities: rubber is much more wear-resistant than steel, iron, and various other metal materials. It can also be adjusted in formulation to resist corrosion from different chemical solvents. Therefore, it is particularly suitable for conveying and controlling pipelines of particle slurry and chemical media.

- Excellent sealing: both ends of the hose are equipped with rubber flanges. When the valve is connected to the pipeline, there is no need to add additional sealing gaskets, thereby eliminating undesirable phenomena such as running, popping, dripping, and leaking.

- Good cold resistance: since the fluid medium flows in the elastic hose, adverse consequences such as shell freeze cracking caused by fluid crystallization are eliminated.

- The structure is scientifically rational, operation is simple and flexible, and maintenance is convenient. During inspections, only the replacement of the rubber tubing is required. The valve body and other components can be used for an extended period, thereby enhancing the valve's service life. This significantly reduces users' production costs, aligning with the principles of value engineering.

- The hose valve has a simple structure and is the only leak-proof valve in China. It can withstand various medium concentrations of acids and any concentration of alkaline salt solution. It can convey ore slurry, dry and wet powders, as well as medium with crystalline objects.

- Different rubber formulations for hoses can be matched with different medium, meeting various production requirements of different users.

Main Dimensions

|

Nominal Diameter |

Dimensions(mm) |

|||||

|

Structural Length |

Center Height |

Outer Diameter |

Center Distance |

Inner Diameter |

Number of Holes - Hole Diameter |

|

|

50 |

195 |

162 |

165 |

125 |

50 |

4-φ18 |

|

65 |

230 |

195 |

185 |

145 |

65 |

4-φ18 |

|

80 |

285 |

237 |

200 |

160 |

80 |

8-φ18 |

|

100 |

365 |

288 |

220 |

180 |

96 |

8-φ18 |

|

125 |

440 |

293 |

250 |

210 |

120 |

8-φ18 |

|

150 |

500 |

447 |

285 |

240 |

145 |

8-φ22 |

|

200 |

540 |

475 |

340 |

295 |

195 |

12-φ22 |

|

250 |

630 |

544 |

405 |

355 |

245 |

12-φ26 |

|

300 |

730 |

595 |

460 |

410 |

295 |

12-φ26 |

|

350 |

890 |

700 |

520 |

470 |

345 |

16-φ26 |

|

400 |

1090 |

760 |

580 |

525 |

395 |

16-φ30 |

|

450 |

1120 |

820 |

640 |

585 |

445 |

20-φ30 |

|

500 |

1240 |

870 |

715 |

650 |

495 |

20-φ33 |