High Pressure Flat Gate Valve

High-Pressure Wear-Resistant Flat Gate Valve Dedicated for Slurry

Product Introduction

The slurry valve, named for its application in mines, is constructed in three parts with a cast valve body and two welded flanges. It features a hard alloy sealing surface and a stainless steel gate, offering a rational structure, convenient operation, and quick opening. With characteristics such as wear resistance, corrosion resistance, long service life, strong interchangeability, easy assembly, low maintenance costs, and high economic benefits, it ensures reliable sealing and prevents issues like "nibbling." This valve is suitable for the cutoff of granular materials in pipelines across industries such as mining, metallurgy, coal, chemicals, and power plants. It stands as the ideal choice for slurry transport systems in China.

Main Features and Performance

- Rational structure, easy operation, long service life.

- Good wear resistance and pressure resistance performance.

- Remote electronic control and hydraulic control can be achieved.

- Vulnerable parts can be quickly replaced. It is easy to assemble, with low maintenance costs and high economic benefits.

- It prevents phenomena like "nibbling."

- The sealing is reliable and the sealing gap is easy to adjust, without dropping and leakage.

- No deposits in the slurry delivery system.

Application Fields

Due to its simple structure, flexible operation, low maintenance requirements, and minimal fluid resistance, this valve is widely utilized in the hydraulic transportation of granular materials in sectors such as mining, power plants, metallurgy, and chemical industry. Especially in medium and high-pressure slurry pipelines, it serves as the ideal valve for upgrading and replacing existing systems.

Applicable Medium

The valve is suitable for two-phase medium, including solids, liquid-solid mixtures, and gas-solid mixtures, such as ore powder, tailings, pulp, wood pulp, fibers, dust, chemical wastewater, sedimentation tank water, ore sands, furnace slag, asphalt, cement slurry, water for power plant, and power plant ash and slag.

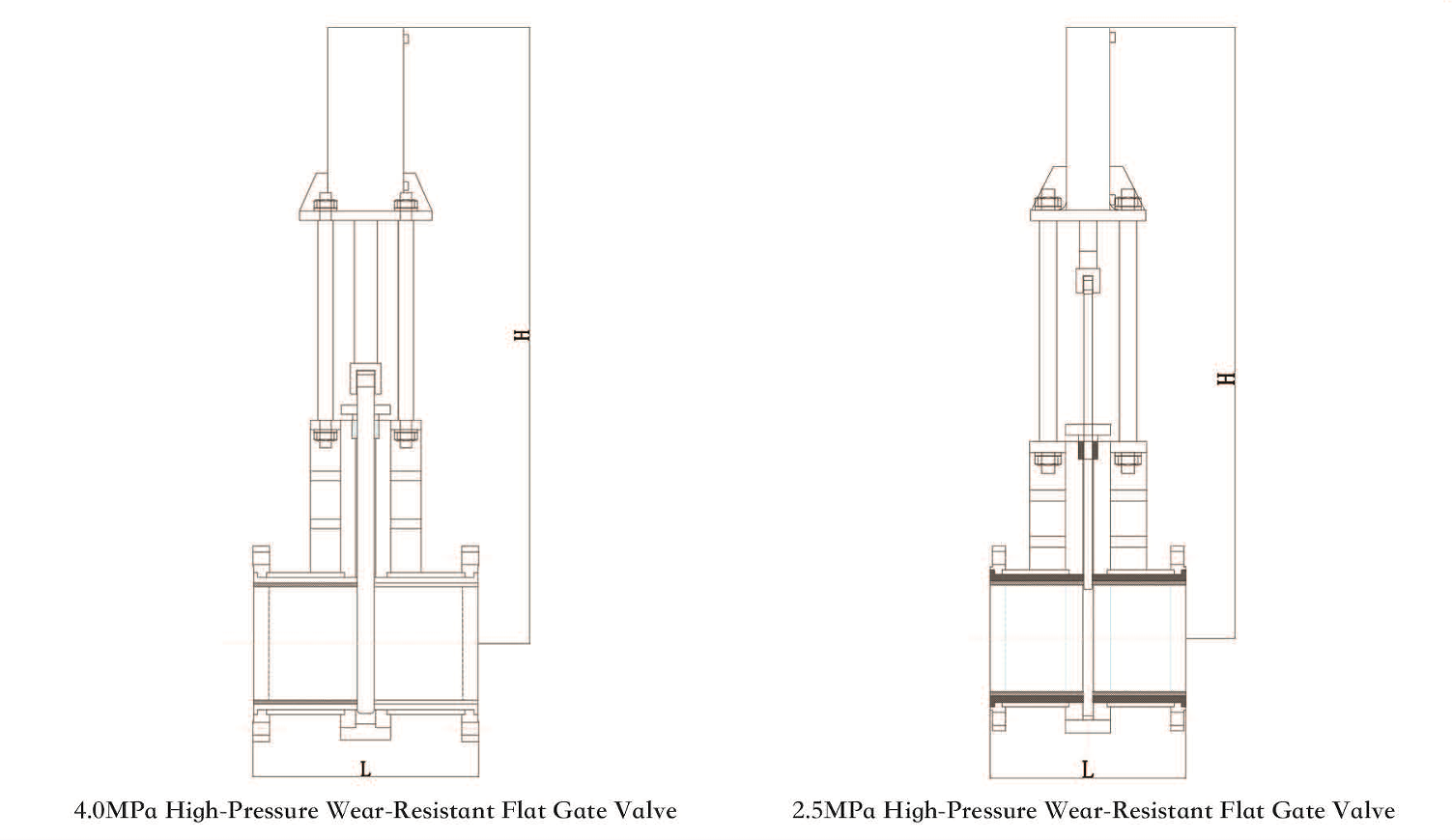

4.0MPa and 2.5MPa Connection Dimensions Table

|

Nominal diameter |

2.5MPa Dimension(mm) |

4.0MPa Dimension(mm) |

||||||||||

|

Center Height |

Structural Length |

Outer Diameter |

Center Distance |

Sealing Surface |

Number of Holes -Hole Diameter |

Center Height |

Structural Length |

Outer Diameter |

Center Distance |

Sealing Surface |

Number of Holes -Hole Diameter |

|

|

150 |

1400 |

350 |

300 |

250 |

218 |

8-M24 |

1450 |

450 |

300 |

250 |

218 |

8-M24 |

|

200 |

1550 |

400 |

360 |

310 |

278 |

12-M24 |

1600 |

500 |

375 |

320 |

285 |

12-M27 |

|

250 |

1700 |

450 |

425 |

370 |

332 |

12-M27 |

1750 |

550 |

450 |

385 |

345 |

12-M30 |

|

300 |

1850 |

500 |

485 |

430 |

390 |

16-M27 |

1900 |

600 |

515 |

450 |

410 |

16-M30 |

|

350 |

2000 |

550 |

555 |

490 |

448 |

16-M30 |

2050 |

650 |

580 |

510 |

465 |

16-M33 |

|

400 |

2150 |

600 |

620 |

550 |

505 |

16-M33 |

2200 |

700 |

660 |

585 |

535 |

16-M36 |