As winter sets in, temperatures drop rapidly, and valves often experience freezing issues. If left unaddressed, this can easily lead to pipeline malfunctions. In high-risk work environments, it could even result in accidents. Therefore, antifreeze measures for valves are crucial.

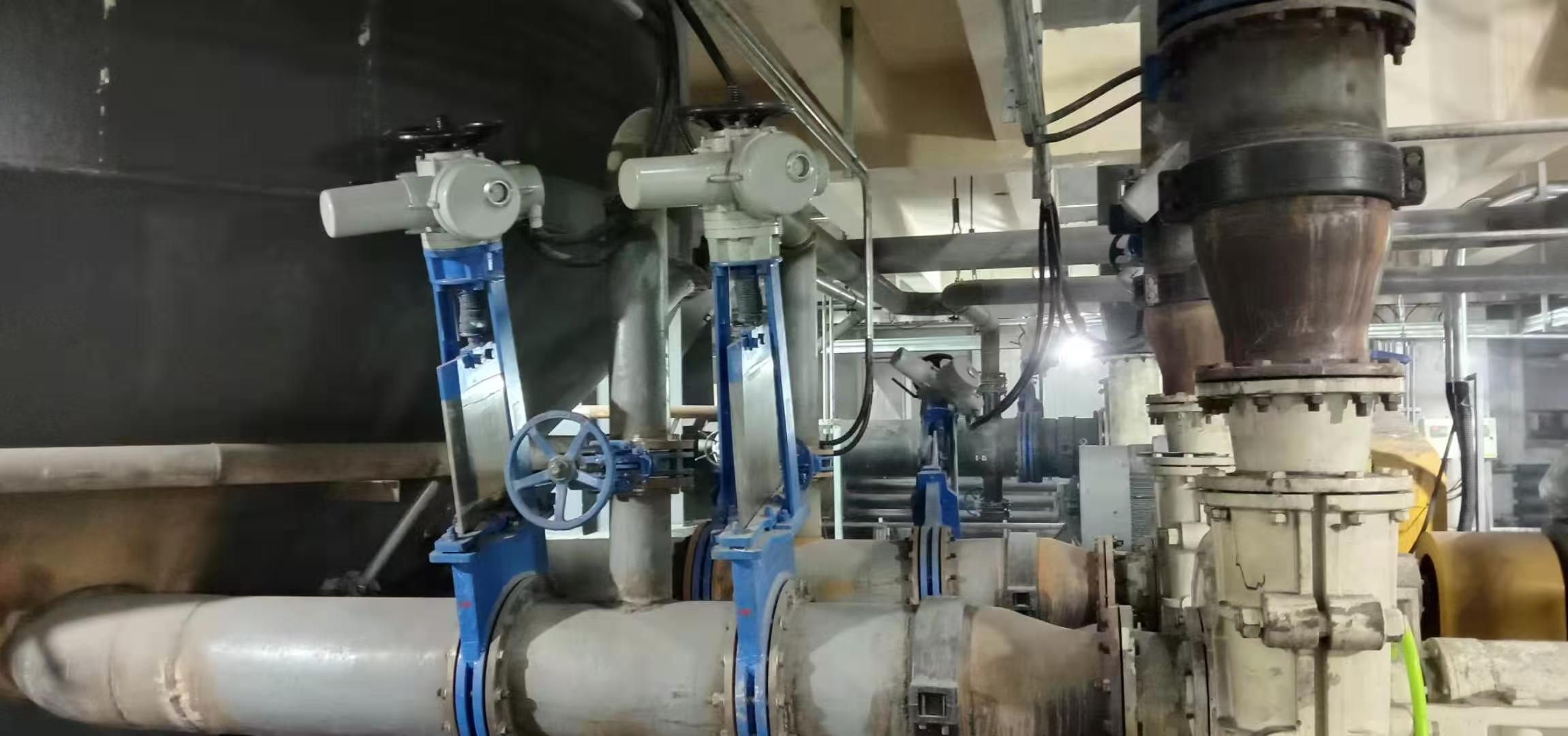

Usage of Valves

Before temperatures fall, it's essential to conduct comprehensive insulation work on valve systems to prepare for winter. Gather the necessary tools: insulation cotton, iron wire, pliers, and a utility knife. In gas areas, carry a functional gas detector as well.

Cut the insulation cotton to fit the valve size using a utility knife. Then, use pliers to trim the iron wire for tying. When wrapping the insulation cotton, tear it slightly to pass it around the valve handle, allowing better coverage of the valve body. Once wrapped, secure the insulation cotton with the iron wire.

Winter Maintenance of Valves

If freezing is detected and the valve cannot function properly, do not strike the valve with a wrench or other heavy objects. The correct approach is to close the valve and use steam or hot water to thaw it before reopening.

For valves not in regular use, drain the medium inside the pipeline to prevent both the pipe and valve from freezing. Ensuring safe production is the duty and responsibility of every enterprise. The importance of antifreeze measures for valves cannot be overstated, as a moment of negligence could lead to irreversible consequences.

Winter Maintenance of Valves