How Much Do You Know About Valve Bolts?

Valve connection bolts are categorized into over 10 performance grades, including 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, and 12.9. Bolts with a grade of 8.8 or higher are made from low-carbon alloy steel or medium-carbon steel and are heat-treated (quenching and tempering), commonly known as high-strength bolts. The others are generally referred to as standard bolts. The bolt grade label comprises two numbers that represent the nominal tensile strength and yield ratio of the bolt material. For example:

- A bolt with a grade of 4.6 means:

- The nominal tensile strength of the bolt material reaches 400 MPa;

- The yield ratio is 0.6;

- Therefore, the nominal yield strength of the bolt material is 400 × 0.6 = 240 MPa.

- A high-strength bolt with a grade of 10.9, after heat treatment, achieves:

- A nominal tensile strength of 1000 MPa;

- A yield ratio of 0.9;

- Thus, the nominal yield strength is 1000 × 0.9 = 900 MPa.

The meaning of bolt performance grades is based on international standards, meaning that bolts with the same performance grade have consistent performance regardless of material or origin. Design specifications require only the performance grade.

For strength grades, "8.8" and "10.9" refer to the shear stress levels of 8.8 GPa and 10.9 GPa. For example, an 8.8-grade bolt has a nominal tensile strength of 800 N/mm² and a nominal yield strength of 640 N/mm². Bolt strength is typically represented as "X.Y" where X×100X \times 100X×100 gives the bolt’s tensile strength, and X×100×(Y/10)X \times 100 \times (Y/10)X×100×(Y/10) gives the yield strength. This follows the labeling rule that the yield strength/tensile strength ratio = Y/10Y/10Y/10. For example, a 4.8-grade bolt has:

- A tensile strength of 400 MPa;

- A yield strength of 400 × 8/10 = 320 MPa.

In addition, stainless steel bolts are often marked as A4-70 or A2-70, with different meanings for these designations.

Measurement

There are two main length measurement systems in the world today. The first is the metric system, with units like meters (m), centimeters (cm), and millimeters (mm), commonly used in Europe, China, Japan, and other Southeast Asian regions. The second is the imperial system, with units such as inches, similar to the old Chinese unit "cun" (inch), widely used in the United States, the United Kingdom, and other Western countries.

Metric system: (decimal) 1 m = 100 cm = 1000 mm

Imperial system: (octal) 1 inch = 8 divisions; 1 inch = 25.4 mm, so 3/8'' × 25.4 = 9.52 mm

For products under 1/4'' diameter, numbers are used to represent the nominal diameter, such as #4, #5, #6, #7, #8, #10, #12.

Threads

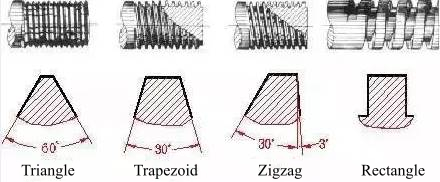

A thread is a shape with a uniform helical projection on the external or internal surface of a solid. Based on structural characteristics and purpose, threads are categorized into three main types:

- General-purpose threads: These have a triangular tooth profile and are used for connecting or fastening parts. General-purpose threads are divided into coarse and fine threads, with fine threads offering higher connection strength.

- Drive threads: These have tooth shapes such as trapezoidal, rectangular, sawtooth, or triangular.

- Sealing threads: These are used for sealed connections, including pipe threads, tapered threads, and tapered pipe threads.

Different Threads Type of Bolts

Thread Fit Grades

Thread fit refers to the looseness or tightness between mating threads. Fit grades specify a combination of allowances and tolerances applied to external and internal threads.

- Unified Imperial Threads:

External threads have three grades: 1A, 2A, and 3A, while internal threads have grades 1B, 2B, and 3B—all clearance fits. The higher the grade number, the tighter the fit. For imperial threads, only grades 1A and 2A have specified allowances, with grade 3A having zero allowance, and the tolerances decrease as the grade number increases.- 1A and 1B: Very loose tolerance grade, suitable for applications where larger clearance is acceptable.

- 2A and 2B: The most commonly used tolerance grade for mechanical fasteners in the imperial series.

- 3A and 3B: Provide the tightest fit for critical applications where high precision and safety are essential.

- For external threads, grade 1A has a 50% larger tolerance than grade 2A, and 75% larger than grade 3A. For internal threads, grade 2B has a 30% larger tolerance than grade 2A; grade 1B has a 50% larger tolerance than grade 2B, and 75% larger than grade 3B.

- Metric Threads:

External threads have three grades: 4h, 6h, and 6g, while internal threads have grades 5H, 6H, and 7H (Japanese standard thread accuracy grades are classified as I, II, and III, with grade II used in general). In metric threads, H and h have zero basic deviation, G has a positive deviation, and e, f, and g have negative deviations.- H is commonly used for internal thread tolerance, generally without surface plating or with very thin phosphating layers. G is used in special cases for thicker coatings but is seldom used.

- g is commonly used for thin coatings (6-9 μm), such as bolts designated 6h on product drawings, where pre-plating threads use a 6g tolerance.

- The best thread fit combinations are H/g, H/h, or G/h. For bolts, nuts, and other precision fasteners, the standard recommends a 6H/6g fit.

- Thread Designation

Main geometric parameters for self-tapping and self-drilling threads:- Major diameter (d1): The diameter of the imaginary cylinder that coincides with the crests of the threads. This diameter generally represents the nominal thread size.

- Minor diameter (d2): The diameter of the imaginary cylinder that coincides with the roots of the threads.

- Pitch (p): The axial distance between corresponding points on adjacent threads along the pitch diameter. In imperial threads, pitch is often expressed by the number of threads per inch (25.4 mm).

Below are common thread pitch specifications for metric and imperial self-tapping threads:

- Metric self-tapping threads:

- Specifications: ST1.5, ST1.9, ST2.2, ST2.6, ST2.9, ST3.3, ST3.5, ST3.9, ST4.2, ST4.8, ST5.5, ST6.3, ST8.0, ST9.5

- Pitch: 0.5, 0.6, 0.8, 0.9, 1.1, 1.3, 1.3, 1.3, 1.4, 1.6, 1.8, 1.8, 2.1, 2.1

- Imperial self-tapping threads:

- Specifications: #4, #5, #6, #7, #8, #10, #12, #14

- Threads per inch: AB thread: 24, 20, 20, 19, 18, 16, 14, 14; A thread: 24, 20, 18, 16, 15, 12, 11, 10